Description

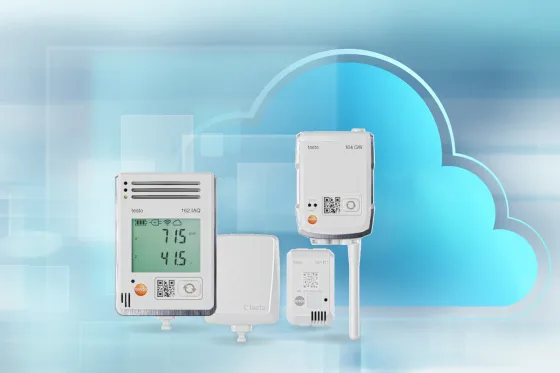

The testo 6681 transmitter fully meets the professional instrument requirements for the industrial sector and has a robust metal housing. In addition to the features and characteristics of the testo 6651, it possesses a range of other advantages. The transmitter is chosen for use in cleanrooms, drying systems, compressed air systems with residual moisture, and complex air conditioning technology.

Features:

- Highest accuracy and long-term stability

- **Replaceable pre-calibrated** testo 6610 series probes

- Special probe versions for measuring **residual moisture**, in **H2O2** atmospheres, and in **polluted environments**.

- **Robust metal housing**

- Optional **ProfiBus DP** bus interface

- Optimal adjustment and calibration capabilities **on-site**

- Optional **Ethernet** interface

- Early warning protocols / **self-monitoring**

- Configuration via **P2A** adjustment and parameterization software or via the instrument menu

- Saving adjustment history/reports in the instrument memory

- All the most common instrument configurations can be ordered via **user configuration**

The most suitable application areas for these measuring solutions are:

- Process control

- Cleanrooms

- Test benches

- Drying processes

- Air quality in production and warehouses

- Relevant applications for ventilation and air conditioning systems

Order Number 0555 6681